Commercial

Industrial

Residential

Other Applications

Get Started

Back

Commercial

Products All Products

Applications

Walls Foundations Roof and Roof Decks Air Distribution Ceilings Interior Solutions Mechanical, Pipe, Equipment Commercial Insulation Homepageㅤ

Product Types

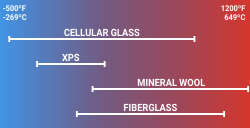

Fiberglas™ Insulation Foamglas® Cellular Glass Foamular® XPS Foamular® NGX® Thermafiber® Mineral Wool Thermafiber® Formaldehyde-Free Perimeter Fire Containment Rainbarrier® Continuous Insulation Accessories All ProductsEnclosure Solutions

Wall Enclosure Solutions Below-Grade Enclosure Solutions Roof Enclosure Solutions All Enclosure SolutionsBack

Industrial

Products All Products

Product Types

Fiberglas™ Fiberglass FOAMGLAS® Cellular Glass FOAMULAR® XPS Thermafiber® Mineral Wool Polymer InsulationBack

Residential

Products All Products

Applications

Attics Floors Walls Air Distribution/Ductwork Air Sealing Basement & Crawl Spaces Specialty Products Residential Insulation Home PageProduct Types

Resources

For Pros

Pink Advantage Dealer Program ProPink vs Competition Document Library ProCat® Margin Estimator AirCare™ HVAC Contractor Program I Am Next GenGet Started

Find Our Products

Find a Distributor Find a Retailer Contact UsGet it Installed

Find a Professional Find an HVAC Professional

Trained. Tested. Trusted.

Certified Energy Experts® help make buildings and homes quiet, comfortable and energy smart.

Back

Other Applications

Back

Get Started